Bangchak Phra Khanong Refinery

A modern complex refinery with a maximum capacity of 120,000 barrels per day.

Developed to be a High Value Specialty Products Refinery for Low Emissions product production.

Able to produce premium grade gasoline and diesel including gasohol and diesel products that comply with the governments Euro 5 standard.

Enhance safety and environmental standards, to maximize efficiency and capacity through 3E and YES-R projects.

Bangchak Sriracha Refinery

A modern complex refinery with a maximum capacity of 174,000 barrels per day.

Over 100 crude and finished oil tanks.

A jetty, off the coast to handle large oil tankers of up to 120,000 tons and three jetties to deliver up to 8,000 tons of oil and chemical products.

Configuration incorporates unique proprietary technologies that provide us with significant flexibility to handle a wide range of crude oils.

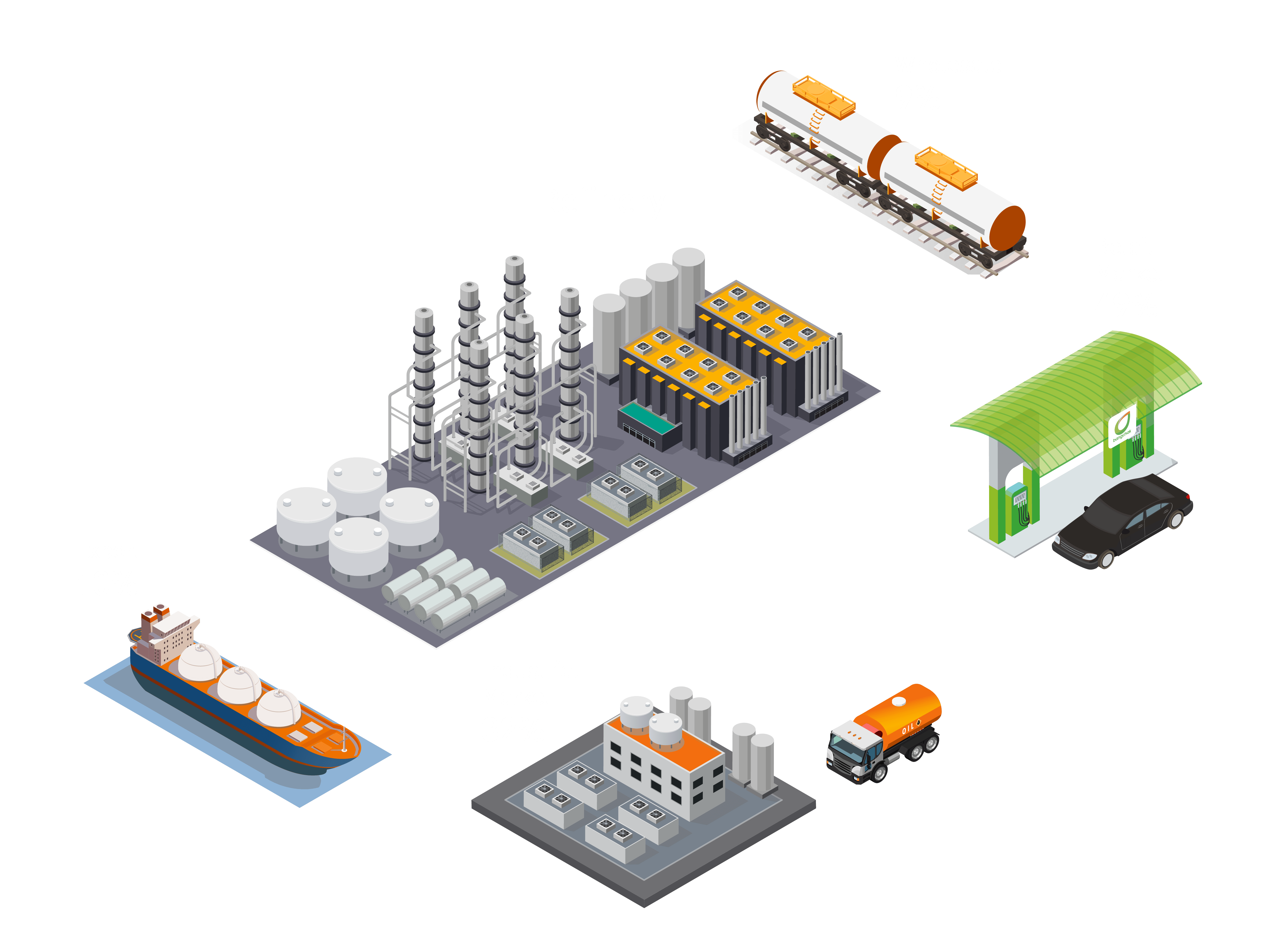

Distribution Channels

Total Sales Volume

Unit: % Portion of total sales volume As of Q4/2024

Refinery Business Platforms

Products

Fuel oil is part of the crude with a high boiling point. It is largely used in the industrial and transport sectors. It also powers marine vessels and power generation.

Produced fuel oil is low sulfur with high quality and environment friendly

| Property | Test Method | Guarantee Specification |

|---|---|---|

| SPECIFIC GRAVITY AT 15.6 DEG.C, G/ML | ASTM D 1298 | 0.97 max |

| KINEMATIC VISCOSITY @ 100 DEG.C | ASTM D 445 | 100 max |

| FLASH POINT, PMCC | ASTM D 93 | 75 min |

| POUR POINT, DEG.C | ASTM D 6749 | 48 max |

| SULPHUR CONTENT, %WT | ASTM D 4294 | 0.3 max |

| GROSS HEAT OF COMBUSTION, CAL/GM | ASTM D 4868 | 9,900 min |

| WATER AND SEDIMENT, %VOL | ASTM D 1796 | 1.0 max |

| ASH CONTENT, %WT | ASTM D 482 | 0.1 max |

Means heavy oil whose molecules are not cracked at HCU, thus high-quality fuel oil with low sulfur and nitrogen contents. UCO is a raw material for basic lube oil production.

| Property | Test Method | Guarantee Specification |

|---|---|---|

| Kinematic Viscosity, @100 Deg C | ASTM D445 | 3.5-5.0 |

| Normalized VI @4.3 cSt | ASTM D2270 | Min 133 |

| Sulfur, ppm | ASTM D5453 | Max 20 |

| Nitrogen, ppm | ASTM D4629 | Max 5 |

| 5% distillation, C | ASTM D1160 | Min 350 |

| Ni+V, ppm | UOP 389 | Max 0.1 |

| Fe, ppm | UOP 389 | Report |

Catering to jet plans, Bangchak’s product is known as Jet A-1, suiting passenger plans or commercial plans in general. Bangchak’s crude oil and distillation process yields low-sulfur jet fuels for lower air pollution and environmental care.

| Property | Test Method | Guarantee Specification |

|---|---|---|

| Appearance | - | Bright & Clear |

| Aromatics | %vol | 25 max |

| Color | Saybolt | report |

| Copper Strip | 2 hrs@100 C | 1 max |

| Density@15 C | g/ml | 0.775 - 0.84 |

| Distillation | C | |

| IBP | C | report |

| 10%vol. | C | 205 max |

| 50%vol. | C | report |

| End point | C | 300 max |

| Residue, %vol | %vol | 1.5 max |

| Loss | %vol | 1.5 max |

| Conductivity | pS/m | 50 - 600 |

| Existent Gum | g/100 ml | 7 max |

| FAME | %vol | 50 max |

| Flash Point | C | 38 min |

| Freezing point | C | -47 max |

| Lubricity | mm | 0.85 max |

| Mercaptan | %wt | 0.003 max |

| MSEP | 70 min | |

| Naphthalenes | %vol | 3 max |

| Particulate Contamination | %wt | 1 max |

| Specific energy | MJ/kg | 42.8 min |

| Stadis 450 | mg/l | 3 max |

| Sulfur | %wt | 0.3 max |

| Thermal stability JFTOT control temp | C | 260 min |

The raw petrol material blended with 10% 20% 85% Ethanol to produce GASOHOL.

GBASE 91

| Property | Unit | Guarantee Specification |

|---|---|---|

| Appearance | - | Bright & Clear |

| Aromatics, | %vol | 38 max |

| Benzene, | %vol | 1.1 max |

| Colour | report | |

| Density @15.0 C | g/ml | reported |

| Distillation | C | |

| 10%vol. | C | 70 max |

| 50%vol. | C | 90 - 110 |

| 90%vol. | C | 170 max |

| End point | C | 200 max |

| Residue | %vol | 2.0 max |

| Solvent wash gum | mg/100 ml | 4 max |

| Lead Content | g/L | 0.005 max |

| MON | - | 78 min |

| Oxidation Stability | min | 360 min |

| Phosphorus | g/L | 0.0013 max |

| Olefins | %vol | 20 max |

| RON | - | 87 min |

| RVP @37.8 C | kPa | 54.5 max |

| Silver corrosion | - | 1 max |

| Sulphur | %wt | 0.005 max |

| Water | %wt | 0.7 max |

The raw petrol material blended with 10% 20% 85% Ethanol to produce GASOHOL.

GBASE 95

| Property | Unit | Guarantee Specification |

|---|---|---|

| Appearance | - | Bright & Clear |

| Aromatics, | %vol | 38 max |

| Benzene, | %vol | 1.1 max |

| Colour | - | report |

| Density @15.0 C | - | reported |

| Distillation | C | |

| 10%vol. | C | 70 max |

| 50%vol. | C | 90 - 110 |

| 90%vol. | C | 170 max |

| End point | C | 200 max |

| Residue, %vol | - | 2.0 max |

| Solvent wash gum | mg/100 ml | 4 max |

| Lead Content | g/L | 0.005 max |

| MON | - | 82 min |

| Oxidation Stability, min | - | 360 min |

| Phosphorus | g/L | 0.0013 max |

| Olefins | %vol | 20 max |

| RON | - | 91 min |

| RVP | 37.8 C | 54.5 max |

| Silver corrosion | - | 1 max |

| Sulphur | %wt | 0.005 max |

| Water | %wt | 0.7 max |

The raw petrol material blended with 7% 10% 20% Biodiesel to produce High-speed Diesel for automobiles, trucks, vessels, boats, and others.

| Property | Unit | Guarantee Specification |

|---|---|---|

| Appearance | - | Bright & Clear |

| Ash | %wt | 0.01 max |

| CCR | %wt | 0.3 max |

| Cetane Index | - | 50 min |

| Color, ASTM | - | 4.0 max |

| Copper Strip | - | 1 max |

| Density@15C | g/ml | 0.81 - 0.87 |

| Distillation | C | |

| 50%vol. | C | to be reported |

| 90%vol. | C | 357 max |

| Flash Point | C | 52 min |

| PAH | %wt | 11 max |

| Pour Point | C | 10 max |

| Sulphur, | ppm.wt | 50 max |

| Visc@40C | cst | 1.8 - 4.1 |

| Water | ppm.wt | 200 max |

Hydrocarbon compounds derived from Bangchak’s processes through a variety of processes as needed by the market. Applications as a blending agent in oil-based paints and other paints, lacquer, and varnish, in cleaning greasy patches, in cleaning machinery and metallic parts, and in lowering asphalt viscosity.

| Properties | Unit | Method | Guarantee Specification |

|---|---|---|---|

| SG @60/60 deg F | - | ASTM D 4052 | report |

| density @15 deg C | g/ml | ASTM D 4052 | report |

| density @30 deg C | g/ml | ASTM D 4052 | report |

| Distillation | |||

| IBP | C | ASTM D 86 | report |

| 10% recovered | C | ASTM D 86 | report |

| 50% recovered | C | ASTM D 86 | 178 max |

| 90% recovered | C | ASTM D 86 | report |

| FBP | C | ASTM D 86 | 200 max |

| %residue | %vol | ASTM D 86 | 1.3 max |

| Flash point | C | IP 170 | 38 min |

| Corrosion Copper strip (3h/100 deg C) | - | ASTM D 130 | No.1 max |

| Existent gum | mg/100 ml | ASTM D 381 | 5 max |

| Total sulfur content | ppm wt | ASTM D 5453 | 10 max |

| Aniline point | C | ASTM D 611 | 48 min |

| Total Aromatics | %vol | ASTM D 6839 | report |

| Doctor test | - | ASTM D 4952 | negative |

| Bromine number | gBr2/100g | ASTM D 1159 | 3 max |

| Acidity of distillation residue | - | ASTM D 1093 | neutral |

LPG is a mixture of hydrocarbons, that is, propane and butane, bottled in the form of liquid in high-pressured iron cylinders. LPG is mostly used as cooking gas in households and can also be used in the industrial sector, such as for refrigerator-paint heating, tobacco heating, glass cutting, iron welding, and iron sheet cutting. Besides, it is an optional fuel for modified gasoline-engine vehicles.

| Properties | Method | Guarantee Specification |

|---|---|---|

| Copper Strip Corrosion | ASTM D1838 | No.1 max |

| Pentane & Heavier Content % vol | ASTM D2163 | 2.0 MAX |

| Odorant | In House | Marketable |

| Residue After Evaporation %vol | ASTM D2158 | 0.05 MAX |

| Total Sulfur ppm.wt | ASTM D6667 | 140 MAX |

| Vapour Pressure @ 37.8 C kPa | ASTM D1267 | 1,380 MAX |

| Water | Visual | nil |

| 95%vol.Evaporated C | ASTM D1837 | 2.2 MAX |

Resembling LPG, this hydrocarbon compound also contains propane and butane (at over 80% in volumetric ratio) and is derived from the hydro-desulfurization cracking unit, ridding it of the LPG odor.

This odorless LPG is used for producing aerosol.

| Properties | Method | Guarantee Specification |

|---|---|---|

| Copper Strip Corrosion | ASTM D1838 | No.1 |

| C3 % vol | ASTM D2163 | report |

| 1_3 butadiene % vol | ASTM D2163 | report |

| C2 % vol | ASTM D2163 | report |

| C4 % vol | ASTM D2163 | report |

| Total Olefins % vol | ASTM D2163 | report |

| Pentane & Heavier Content % vol | ASTM D2163 | 2.0 MAX |

| Residue After Evaporation %vol | ASTM D2158 | 0.05 MAX |

| SG @ 15.6/15.6 C | ASTM D1657 | report |

| Density @ 15 C g/cm3 | ASTM D1657 | report |

| SG @ 30/30 C | ASTM D1657 | report |

| Total Sulfur ppm.wt | ASTM D6667 | 140 MAX |

| Vapour Pressure @ 37.8 C kPa | ASTM D1267 | 1,380 MAX |

| Water Entrained | Visual | nil |

| Volatility, 95%vol.Evaporated C | ASTM D1837 | 2.2 MAX |

is an alternative fuel to replace diesel fuels, using feedstock from waste, namely “used cooking oil” and it is regarded as environmentally friendly clean energy. UCOME is produced from used cooking oil in transesterification process using methanol.

| Property | Test Method | Guarantee Specification |

|---|---|---|

| Methyl Ester content, % (m/m) | EN 14103 | Min 96.5 |

| Density at 15C, kg/m3 | EN ISO 12185 | 860 - 900 |

| Kinematic viscosity at 40C, cst | EN ISO 3104 | 3.5 - 5 |

| Flash point, degC | EN ISO 3679 | Min 120 |

| Cloud Point, degC | Report | |

| Cold filter plugging point, degC | EN 116 | Report |

| Sulfur content, ppm | EN ISO 20884 | Max 10 |

| Carbon residue on 10% distillation residue, % (m/m) | EN ISO 10370 | Max 0.3 |

| Cetane number | IP 498 | Min 51 |

is an alternative fuel to replace diesel fuels, using feedstock from waste, namely “used cooking oil” and it is regarded as environmentally friendly clean energy. UCOME is produced from used cooking oil in transesterification process using methanol.

| Property | Test Method | Guarantee Specification |

|---|---|---|

| Sulphated ash content, % (m/m) | ISO 3987 | Max 0.02 |

| Water content, mg/kg | EN ISO 12937 | Max 500 |

| Total contamination, mg/kg | EN 12662 | Max 24 |

| Copper strip corrosion | EN ISO 2160 | 1 |

| Oxidation stability at 110C, h | EN 14112 | Min 6 |

| Acid value, mg KOH/g | EN 14104 | Max 0.5 |

| Iodine number, g lod/100g | EN 14111 | Max 120 |

| Linolenic acid methyl ester, % (m/m) | EN 14103 | Max 12 |

| Methanol content, % (m/m) | EN 14110 | Max 0.2 |

is an alternative fuel to replace diesel fuels, using feedstock from waste, namely “used cooking oil” and it is regarded as environmentally friendly clean energy. UCOME is produced from used cooking oil in transesterification process using methanol.

| Property | Test Method | Guarantee Specification |

|---|---|---|

| Monoglyceride, % (m/m) | EN 14105 | Max 0.8 |

| Diglyceride, % (m/m) | EN 14105 | Max 0.2 |

| Triglyceride, % (m/m) | EN 14105 | Max 0.2 |

| Free glycerin, % (m/m) | EN 14105 | Max 0.02 |

| Total glycerin, % (m/m) | EN 14105 | Max 0.25 |

| Group I metals; Na+K, mg/kg | EN 14108/14109 | Max 5 |

| Group II metals; Ca+Mg, mg/kg | EN 14538 | Max 5 |

| Phosphorus, mg/kg | EN 14107 | Max 10 |