21 June 2024

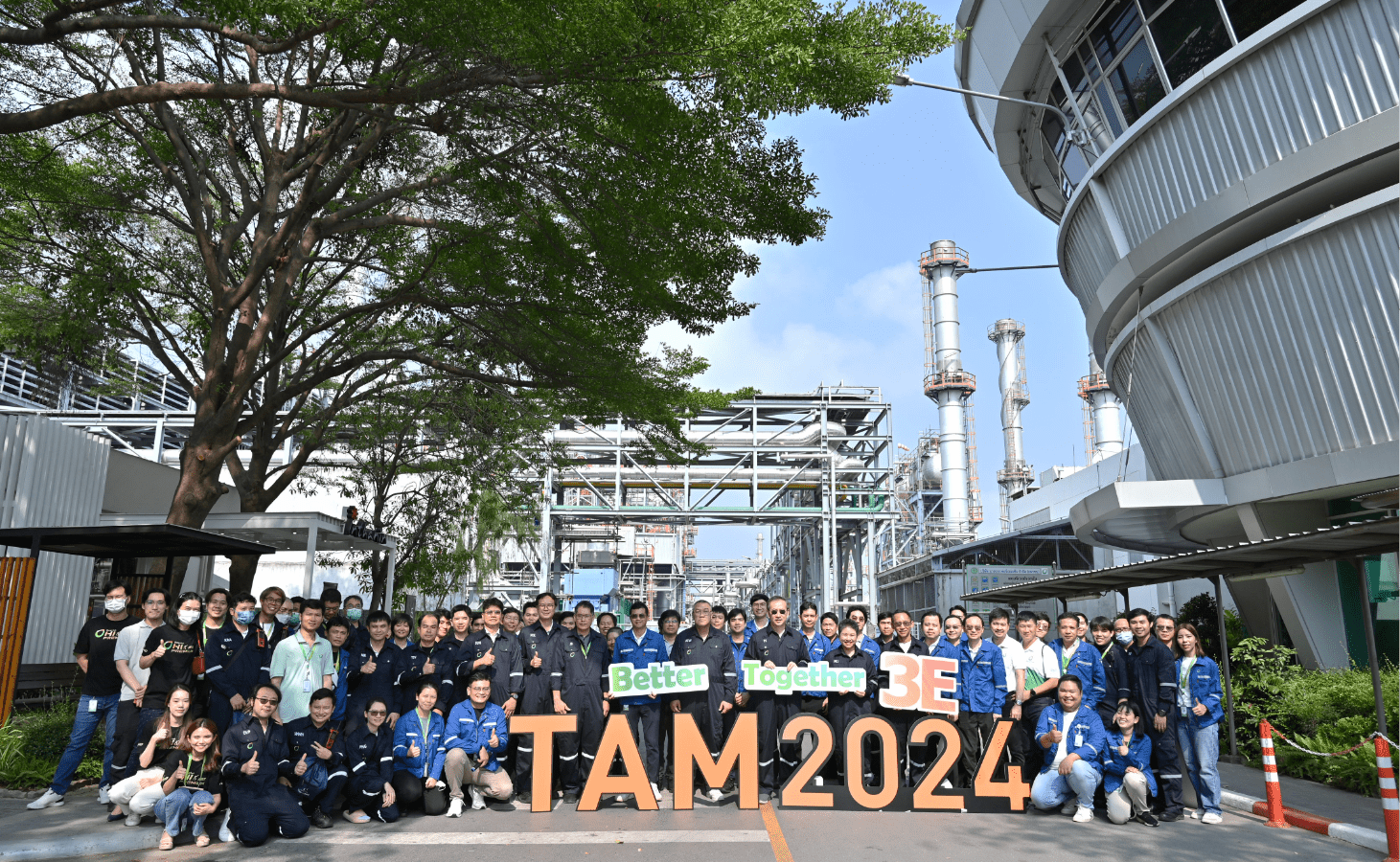

Bangchak Phra Khanong Refinery achieved a new TAM record

with utmost safety, maintaining refining efficiency.

One of the critical tasks of an oil refinery is to perform Turnaround Maintenance or TAM. This refers to the periodic major shutdown for inspections, restorations, repairs, and maintenance of machinery, equipment, and systems involved in continuous refining operations. All refineries must plan for this critical process, during which all production operations are halted, and maintenance work is carried out before safely resuming regular operations. This usually takes approximately 30-45 days, depending on the size, capacity, and other variables. Refineries coordinate with one another to collectively schedule these periods to avoid impacting the country’s overall production capacity.

Bangchak Phra Khanong Refinery regularly schedules Turnaround Maintenance, shutting down refining units to maintain and improve the efficiency of crude refining and other processes. This ensures safe operations and mitigates risks to the community and the environment. The most recent TAM was conducted in 2021.

The 2024 TAM to enhance efficiency lasted a record-breaking 27 days in May, the shortest duration ever achieved.

Best practices were implemented to reduce the time required for maintenance work, incorporating drones and robots to conduct proactive equipment inspections for maintenance planning. High-performance tools such as Intelligent Pigging were used to clean pipelines, and Coating Furnace Technology was employed to reduce energy consumption in furnaces. Skilled personnel, including specialists from Bangchak Sriracha Refinery and international QA/QC experts, were present to ensure that all work processes adhered to global standards and safety regulations. Moreover, environmental management was prioritized with equipment designed to minimize environmental impact and enhance safety, resulting in Zero Lost Time Injury throughout the TAM period.

These operations allowed Bangchak Phra Khanong Refinery to consistently maintain its high refining capacity (130,000 barrels per day), increase the production proportion of SAF to address the growing demand from the aviation sector and support the SAF production plan, and the production of premium-grade Unconverted Oil. Additionally, the extension of the frequency of TAMs from every two years to every four years was able to reduce costs and enhance competitiveness. This is achieved by installing units to improve efficiency and stability, such as the Enclosed Ground Flare (EGF) Unit 2 and cogeneration power plant and the commencement of construction for the SAF production unit from used cooking oil. Furthermore, production energy management was enhanced to achieve the highest Energy Intensity Index (EII) – Quartile 1 Level, which directly contributes to Bangchak’s greenhouse gas reduction measures as outlined in the BCP 316 NET Plan, aiming at Carbon Neutrality by 2030 and Net Zero GHG Emissions by 2050.

Furthermore, the TAM generated income for the communities surrounding the refinery through the “Community Kitchen” project. The initiative allowed the community to open 24 shops, with representatives from eight different communities, generating over eight million baht and additional income from laundry services for employees amounting to approximately 200,000 baht. These initiatives have played a significant role in stimulating the grassroots economy.